How can we help you?

Metallurgy - Corrosion, Weld Issues, New Builds

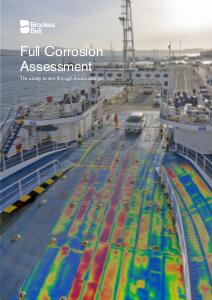

The maritime and energy industries put metallic components through the toughest of challenges.

Offshore, onshore and shipboard operating conditions alike can create punishing loads and environments for metallic components. So, it’s important that you have confidence that your key assets are up to the job.

Brookes Bell’s metallurgy root cause failure analysis, surveying and inspection services will give you that confidence, whilst the metallurgical services at The Lab can provide an extra level of forensic detail covering failure investigation if required.

Maritime metallurgy, surveying and inspection services

Brookes Bell’s metallurgy services cover a broad range of different scenarios. From verification of material selection and quality for a new fabrication project, to inspecting assets on-site, to finding out what happened in the event of a failure, Brookes Bell can provide metallurgical support throughout the complete lifetime of your project or asset:

Key contact

Brookes Bell: a simple solution to your complex problem

At Brookes Bell, we understand that issues and problems rarely occur in isolation.

You may have an issue with corrosion, but this may well be linked to other issues.

Instead of sourcing a team of experts from multiple providers, source them from a single point of contact - Brookes Bell.

This not only generates immediate cost savings, but longer-term savings in administration, invoicing, project management, complete visibility over your supply chain and more.

We offer a truly multidisciplinary service. We can draw upon the expertise of disciplines and expertise across diverse, but related, fields such as Master Mariner services, salvage and wreck removal, scientific and cargo expertise, fire and explosion investigation, paint and coatings and many more.

Speak to Brookes Bell about your metallurgy surveying and inspection requirements today.