The Lab at Brookes Bell’s state of the art PEC (Pulsed Eddy Current) array scanners can rapidly test substrates with a sweeping probe width of 450mm, penetrating up to 300mm.

The innovative technology enables our in-house NDT specialists to scan large volumes of deck plating and other structural hull surfaces.

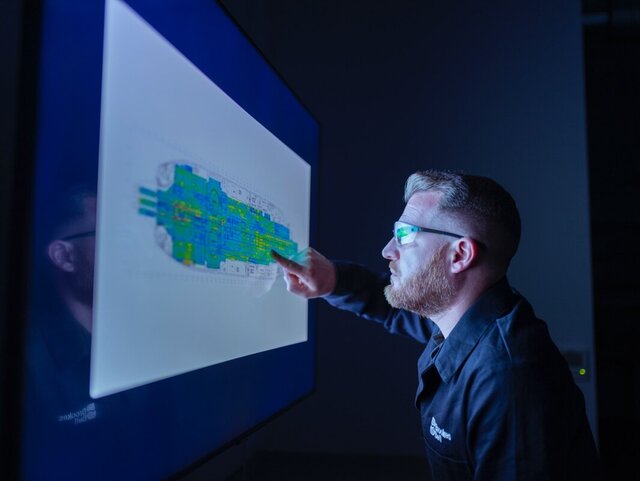

With our unique proprietary software, we are able to recreate precise models of a ship’s structural condition using high resolution imaging, all within a short time frame, allowing for timely decision making prior to going into a refit.

Corrosion mapping applications for vessels include:

- CUI – corrosion under insulation

- Composite decks

- Scab corrosion under antifouling

- Tanks – water/fuel/ballast

- Hull and other exterior painted surfaces

- Seawater and exhaust pipework

- Drencher system pipework

- Flooring in bathrooms/showers/galleys, including through tiled flooring

Our innovative technology conforms to ISO 20669 and allows us to see through composite/anti-slip deck coverings to scan the vessel’s deck structure below.

We can scan hulls above or below the waterline; seeing through non-conductive cladding, finished coatings and antifouling. Our PEC is the ‘go to’ technology for:

- Determining remaining plate thickness

- Plate renewal estimation

- Identifying composite covered areas requiring replacement

- Identifying coating areas to be repaired

Our technology brings a range of benefits compared to traditional scanning methods:

- Our scanners are portable so scans can be undertaken anywhere in the world

- Scans can be carried out months prior to project commencement ensuring minimal disruption

- Scans can be carried out above or below the waterline with no need for the removal of surface material or use of sprays, gels, and dyes

- Speed of data acquisition and generation of report

Benefit to the vessel – how can a PEC corrosion assessment help?

The benefit of a Brookes Bell survey is that the resultant report allows for an accurate quote for steel renewal and repair works, prior to or, during a refit or overhaul with minimum disruption to a vessel’s operations.

Additional benefits include:

- Management company/shipyards will understand the scope of work and can prepare and align schedules, budgets, and interface of subcontractors well in advance

- All parties will have a clear view of the project and can see the full scope of the underlying issues prior to the commencement of work

- The inspection can be carried out months in advance of a yard period to suit the vessel’s schedule

To find out more about The Lab’s full corrosion assessment services, contact us today.