Brookes Bell has been at the forefront of changes in stability regulation, assisting both regulators with rule development and industry with their efficient implementation.

Our extensive expertise in accident investigation gives us a unique insight and perspective to stability, allowing us to implement stability rules in a safe and practical way.

We have two primary tools for stability; NAPA and GHS.

NAPA

For over 30 years NAPA has been developing and scaling software platforms for the maritime industry.

It is the most widely used naval architecture design package and it allows us to work collaboratively with shipyards and other designers.

Here at Brookes Bell we use NAPA’s ship design software to ensure that the vessels we design are safe, competitive and offer the best possible performance.

NAPA’s software platform has a number of features that make it stand out:

- It provides a single source for design information, which means that we are working from a continually updated, single point of truth

- It has been specifically designed for use in the maritime industry and has been proven to be the fastest system for 3D product modelling

- It has had decades of development poured into it, making it a truly unbeatable platform

Thanks to these features, NAPA’s platform has a multitude of benefits:

- It provides more accurate results in earlier design stages

- It is excellent at design change and automation

- NAPA ensures that the platform supports the myriad rules and regulations that apply to shipbuilding

- NAPA can provide analysis of collected data for ship operation. This means that we are able to use real-world data to create better ship designs

GHS

GHS, also known as General Hydro Statics (GHS), is the industry standard software for stability and longitudinal strength modelling for salvage purposes.

One of the core reasons for GHS being the ‘industry standard’ is because it uses a programming language which allows the user to model any operation in some of the most complex grounding scenarios.

In addition to this, GHS also has a built-in flooding module which can be used to generate model sinking scenarios.

Brookes Bell’s naval architects typically use GHS to model a variety of scenarios. These are detailed below:

Salvage modelling

How will a stranded vessel react to a salvage operation? GHS can answer that question.

Our team uses GHS to model outside pulling forces which we use to model chain pullers, strand-jacks and heavy lift ships.

With this feature we are able to assess all steps in almost any salvage operation.

This type of analysis is normally used to assess tenders in complex wreck removal operations.

Grounding and multibody

GHS is the only grounding software that can model any grounding configuration. This makes it a critical part of the assessment of any shipping casualty.

GHS also includes a multibody software which can be used to analyse multiple vessels that may be connected.

These features mean that GHS can be used to model docking and float on operations.

Sinking

Vessel capsizes and sinkings continue in the industry for a variety of different reasons, often with loss of valuable cargoes and even tragic loss of life.

GHS includes a flooding module that can calculate the flow of water in a sinking vessel and its resulting change in floating position, through to its eventual foundering.

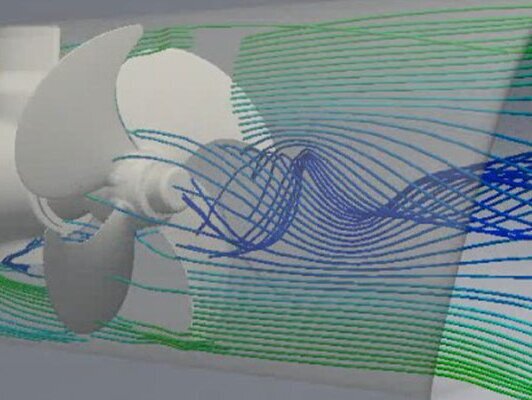

This feature can also be used in conjunction with finite element analysis (FEA) and computational fluid dynamics (CFD) modelling to investigate the causation of sinking vessels.

Parbuckling

Because GHS can model both pull forces and complex groundings means we can accurately model step-by-step parbuckling operations.

This includes making assessments of longitudinal strength, maximum pull force and critical grounding loads.