From Flake to Failure: The Cost of Ignoring Modern Marine Coatings Challenges

Maintaining a vessel’s protective coatings is essential for its longevity and operational efficiency. Despite representing up to just 2% of a ship’s newbuild cost, hull coatings can determine a vessel’s long-term fate. Dr Raouf Kattan of Safinah Group estimates that without effective anti-corrosive coatings, a ship’s steel structure would last just five years, compared with two decades when properly painted.

Despite advances in the field, modern coating technologies can still fail, whether due to application errors, material faults or environmental factors. Dr Holly Edwards, Materials Laboratory Technical Lead at The Lab at Brookes Bell, explains how scientific forensic analysis is helping to uncover the root causes of paint failures, helping shipowners avoid costly downtime and premature corrosion risks.

Why coatings matter

Marine coatings do more than preserve aesthetic appeal; they form a thin film of corrosion protection over a vast steel structure endures constant exposure to harsh marine environments, shielding the metal from saltwater, UV radiation, and chemical damage during the vessel’s operational life. Given their small share of build costs, painting often attracts minimal design attention, yet failures, even minor ones, can force vessels out of service.

“Paint is literally the skin of a ship,’ Holly observes. “When it fails, water or marine growth can penetrate directly to the steel, accelerating corrosion. Owners can face weeks of unexpected dry-docking, plus the cost of replacing thousands of square metres of coating and, in severe cases, steel renewal.”

According to Holly, the most frequent issues fall into three categories: surface-preparation errors, incompatible coating layers and environmental damage.

Surface-preparation errors occur when the steel substrate is not blasted to the correct profile or residual grease remains. Coatings cannot bond properly under these conditions, leading to blistering, flaking or under-film corrosion. Delamination can also occur when incompatible layers trap moisture or solvents. Environmental damage follows exposure to ultraviolet light, extreme temperatures or aggressive biofouling, all of which can degrade polymers and result in softening, chalking or erosion.

“When we analyse paint failure samples, we often find that the problem started with inadequate surface preparation,” Holly explains. “On one vessel we investigated, the primer wasn’t fully cured before the topcoat went on, so the paint simply delaminated. In another instance, residues from masking tape at weld edges caused blistering because moisture became trapped under the film.”

How science helps

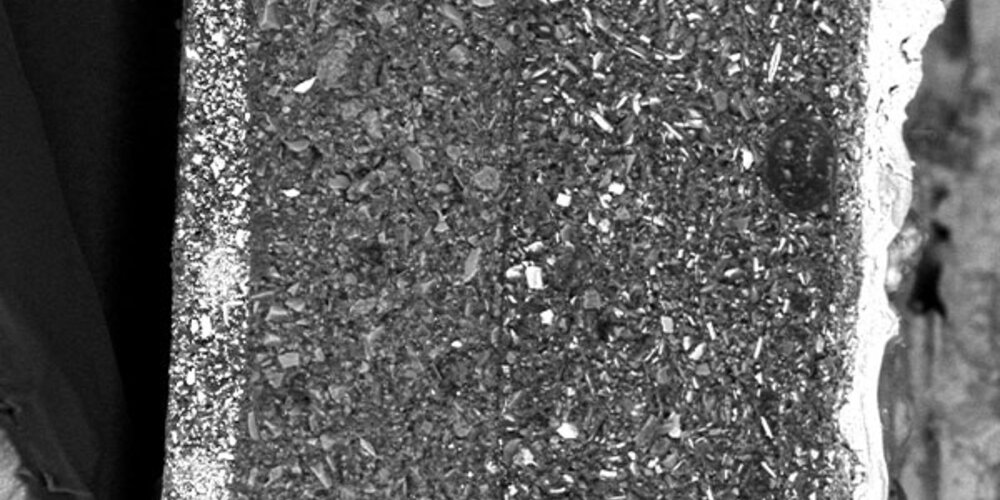

The Lab applies a multidisciplinary scientific approach when it comes to analysing coating failures. Samples of paint flakes and rust particles undergo chemical and metallurgical analysis to identify pigments, binders and corrosion products.

“I’m fascinated by how microscopic evidence tells a story,” Holly says. “Mapping cross-sections of failed coatings shows us precisely where adhesion broke down. From there, we can recommend revised surface-preparation procedures or more compatible product systems.”

The industry is now championing data-driven coating selection, insisting that shipowners need independent performance data rather than relying on generic rules. Holly agrees. “Every vessel has a unique operational profile. Route, speed, water temperature and port dwell times all affect coating performance. We collate failure data across fleets, helping owners choose products that endure their exact conditions.”

Holly emphasises that The Lab’s expertise is not confined to marine vessels. “Our methodologies apply to any steel or composite structure, anywhere in the world,” she explains. “Whether it is an offshore platform, a bridge or a petrochemical plant, we can analyse coatings, corrosion and failure-mode data to advise on the most effective maintenance strategies.”

As the industry explores biocide-free and ‘smart’ coatings with embedded sensors, The Lab’s forensic expertise will become ever more crucial. By combining rigorous forensic analysis with tailored inspection programmes, The Lab is helping shipowners transform a modest 2% investment in coatings into two decades of asset protection and operational reliability.

- Author

- Anthony York

- Date

- 30/07/2025