What is required to be segregated by positive isolation?

All means of common communication between two, or more different products, be they liquid or vapour, must be positively segregated.

These common links would include all liquid and vapour lines plus tank cleaning lines, but not cargo heating systems, since they have no open communication between the differing products.

This includes any ‘small bore’ lines, including stripping lines, clearing lines, drain lines and cross-connection lines. Any and all lines, liquid or vapour, that connect between two dissimilar products must be positively segregated.

All this takes time and effort, what are the regulations behind this?

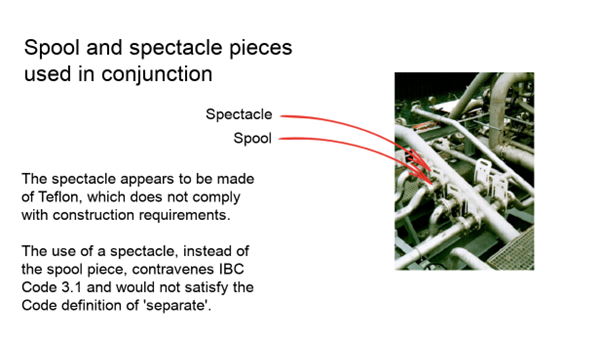

The IBC Code (3.1) states that for cargoes that are required to be segregated from each other due to the possibility of a hazardous reaction occurring between them, are required to be separated (3.1.4) by either of two means:

- By removing spool-pieces or valves and blanking the pipe ends; or:

- By arranging two spectacle flanges in series, with provisions for detecting leakage into the pipe between the two spectacle flanges.

Separate is also defined by the Code (1.3.32) as a cargo piping system or cargo vent system that is not connected to another cargo piping or cargo vent system.

Cargoes that are subject to this IBC Code requirement, can be identified by the code 15.12.3 (Toxic products) in Column ‘o’ of Chapter 17 ‘Summary of minimum requirements’.

The term ‘Positive segregation’ is commonly used to describe such ‘separate segregation’.

Apart from the few ‘Toxic Products’ identified in the IBC Code, there are no regulatory requirements for products to be ‘positively segregated’, therefore for most products, segregation is driven by commercial interests.

However, for any disputes arising from contamination, the first, and immediate, response is to study the isolation or segregation methods conducted between the contaminated cargo and all other spaces.

Should the means of segregation be found to be conducted by valves alone, then this is likely to be considered the source of the contamination and be put under intense scrutiny.

Are means of ‘positive segregation’ commonly fitted to chemical tankers?

Only those chemical tankers carrying products with the nomination 15.12.3, and identified as such in the Vessel’s Certificate of Fitness, are required to be fitted with the methods described in the IBC Code Section 3.1.

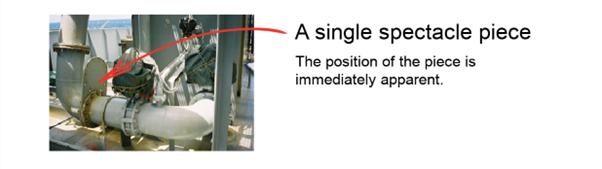

However, methods of providing ‘positive segregation’ that do not fully comply with the Code are commonly fitted. These may include insertion of a spade in a pipeline or by a single spectacle piece.

How thick should a spade or spacer be?

As a rule of thumb, the following formula can be used to calculate the thickness of the required spacer:

(P X D) / 10 = T (mm)

P = System pressure (Barg) / D = Line Diameter (in) / T = Spacer thickness (mm)

Errors in using isolation pieces

Shipboard modifications may result in contraventions of the IBC Code and others. The example below depicts a modification made in good faith; however, several codes are broken.

How do you identify pipeline isolations?

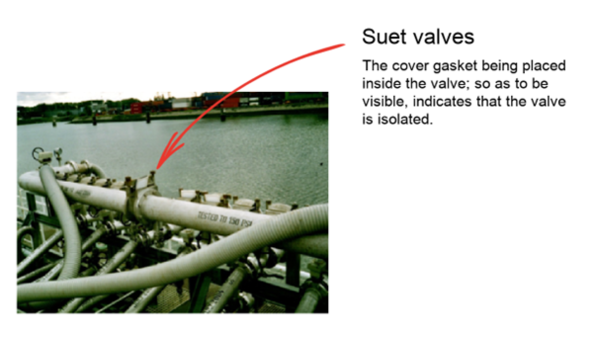

Segregations conducted by means of spool pieces and spectacle flanges will be immediately apparent; however, those made by blind or Suet flanges/valves will require a means of identification.

Blind flanges should be constructed such that they can be readily identified, for example, by means of a ‘tail’ that protrudes above the pipeline when the flange is in position.

Suet valves should, when in use, have the cover left in the open position. These valves may also have a ‘tail’ so that the valve cover cannot be closed when the isolation is in place.

How do you record pipeline isolations?

All pipeline isolations should be the subject of a work order and recorded as such.

Cargo plans should be prepared with line diagrams indicating the segregation points.

Tap into Brookes Bell’s tanker operations expertise

As this article has just demonstrated, the handling and carriage of chemical cargoes is highly complex and provides operators and charterers with a unique set of challenges.

If you want to overcome those challenges successfully, then Brookes Bell can help. Our Master Mariners attend and advise on all aspects of tanker operation including navigation, cargo operations, cargo quality, cargo quantity, tank preparation, port safety, vetting, charter parties and tanker surveys.

Find out more about Brookes Bell’s tanker operations services now

For more maritime industry insights, news and developments, explore the Brookes Bell News and Knowledge Hub…

IMO Maritime Safety Committee Sets Out New Recommendations | Sampling and Analysis | Marine Coatings: First Line of Defence for Corrosion and Cargo Protection