Browse our services

Explore how Brookes Bell can help you

Find an expert

Meet our team, find and expert and connect

Contact us

Get in touch, we're here to help

Today - Monday 24th April - marks World Corrosion Day, an initiative from the Association for Materials Protection and Performance (AMPP). The awareness day has been created to act as a reminder that ‘rust never sleeps’.

Corrosion is one of the biggest maintenance challenges in the maritime industry, costing shipping companies between $50bn to $80bn each year, according to some estimates. On a broader scale, the AMPP has estimated that the cost of corrosion tops 3.4 percent of the global domestic product (GDP).

In other words, corrosion is a big problem.

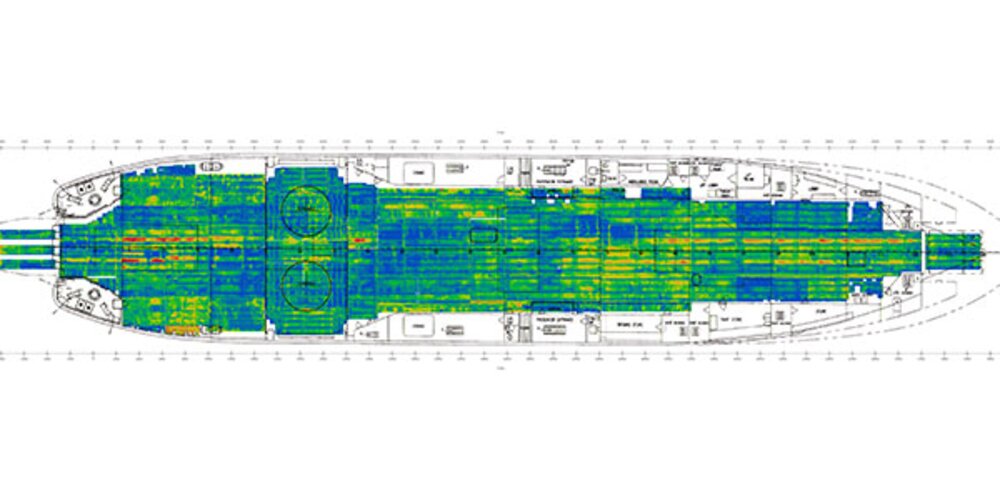

As such, it’s vital that shipping companies, charterers, insurers and others stay on top of corrosion and regularly monitor and assess asset integrity.

Being proactive on corrosion can yield significant cost savings. The AMPP states that employing corrosion control practices could lower the global cost of corrosion by some 15 to 35 percent:

“These significant cost reductions are in addition to the many unquantifiable environmental and public safety benefits that result from long-term, predictable asset integrity,” said Alan Thomas, AMPP CEO. “The many professions that focus on corrosion control are responsible for preventing catastrophic failures that can result in risks to public safety, lost productivity, environmental degradation, or fatalities”.

It pays - literally - to stay on top of corrosion and ensure that vessels and other assets are in top condition.

Here at Brookes Bell and The Lab we offer an industry-leading metallurgy consultancy service that can not only determine the extent of corrosion, but also suggest cost-effective solutions.

Our team has experience applying their metallurgical expertise to many different use cases, including (but not limited to):

So, whether you require assistance with the investigation of corrosion, or you’re looking for proactive advice to prevent corrosion in the first place, Brookes Bell can help.

Find out more about Brookes Bell’s metallurgical consultancy and The Lab’s NDT services.

For more maritime industry news, insights and developments, read the Brookes Bell News and Knowledge Hub…

Innovative Graphene-Based Propeller Coatings to Be Used by Stolt Tankers | What Is Metallurgy and How Is It Used in the Maritime Industry? | What is Tribology?